Veer-O-Metals has the following manufacturing capabilities to support any kind of production facility.

Array of stamping press 10T to 400T with die cushion, coil feeder, compactable for both compound tools & progressive tools.

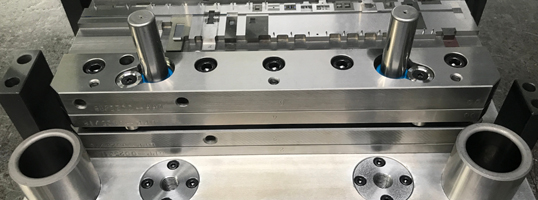

Design & manufacturing of stamping tools, including compound & progressive dies & moulds, jigs & fixtures for fabrication and assembly.

CNC FIBRE laser cutting machines up to 4kW with sheet cutting range 2mtrs x 4mtrs, with pallet changers and tube cutting option.

NCT presses 20T to 30T with turret and linear tool magazine with automated stacking racks & cutting size 1250mm x 2500mm without reposition and also further X axis with multiple repositioning.

CNC bending machines tonnage ranging from 35T to 150T with bed length up to 4meter & multiple axis back gauge positioning with ADS & Laser correction.

MIG, TIG, Brazing, Spot, Resistance, Stud, & Projection welding to weld Mild steel, Stainless steel, Galvanized steel, Copper & Aluminium alloys.

Sonderhoff Foam-in-place ( FIP) machine having Robotic arm - range 3mts x 1.5mts.

4- axis vertical machining centers, CNC turning, SPM’s, expertise in processing - Magnesium alloy, Aluminium castings, Extrusions.

Hydro Pneumatic presses from 1T to 10T for clinch nut insertion of clinching fasteners of all types for Mechanical & electro mechanical assemblies. Dedicated semi-automated mechanical and electro-mechanical assembly lines.

Established wide range of measuring instruments compactable for digitization: CMM - Zeiss make, portable CMM - Faro make, profile projector and testing equipment for special processes.

Heat sink wrapping system and export packing process line.

Powder Coating: Automated plant with 7 zone Nano ceramic pre-treatment and multiple roll on /roll off with reciprocators including high temperature resistance powder coating process.

Liquid spray painting: Augmented with epoxy, polyurethane & air drying.

Our Additive Manufacturing Machine

EOS M 290

Build volume :250x250x325 mm